A rotary vane pump is a positive displacement pump that is made up of rotor-mounted vanes that rotate within a closed cavity. Rotary vane pumps are used in a number of hydraulic pump systems, as well as in vehicles that have automatic transmission and power steering.

Did you know the leading cause of water well problems today is the presence of iron? In fact, iron-laden well water is a fairly common occurrence that can be quite easily and inexpensively remedied via a water well clean-out service.

You probably already know that air compressor technology is used extensively in manufacturing. Care to guess what percent of manufacturing industries rely on air compressors to some extent? If you guessed 70 percent or so, you're right.

What is a well log? It is a document consisting of information regarding your well and will vary according to the state you reside in. We usually file well logs on completion of new wells.

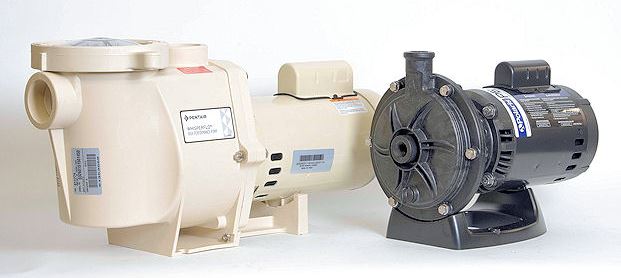

When buying a pump, think about being energy efficient. An oversized pump can cost more to run and have reduced performance.

How do capacitive switches on sump water pumps work? These high tech switches use a microprocessor to assess water levels – and when water reaches a certain point the switches turn the pumps on. One of the main benefits of capacitive switches is that have a long lifespan and are incredibly easy to maintain.

Submersible well pumps are engineered to last a very long time, but a variety of factors can have an adverse effect. Water that has a relatively high volume of natural minerals, sand, silt, or contaminants can cause corrosion and shorten the pump’s lifespan.

One of the smallest pumps on the face of the planet is natural not manmade. Recent scientific research revealed hummingbirds are able to efficiently extract flower nectar because their tongues act more like miniature pumps than straws.

With 2-wire submersible well pumps, the starting components are in the pump and motor itself. This means that there’s no need to take up a bunch of space above ground with a control box, and that the starting components are well protected.

If you have suddenly stop water flowing through a water pump, the pressure from that water will be transmitted back to the pump. This is called a water hammer, but a water pump expert can install your pump correctly to minimize water hammer damage.

Submersible well pumps are built for the long-haul. When the long, cylindrical pumps are installed inside the well casing, they can’t be readily accessed for repair or maintenance. As a result, submersible pumps are extremely durable and may last 20 to 30 years.

In sizing the well pump you are going to have installed, one thing to keep in mind is if there’s going to be adequate water pressure. The pressure must be sufficient to force the water through the piping system to the highest outlet.

The term head is a measurement of the kinetic energy that pumping systems create. The main reason to use this measurement is because different liquids will have different pressures, but the head will not change.

Well water that is too hard means that there is too much manganese or iron in it and that it will require a softener to treat it. Well water testing is able to detect such common problems as well as cloudy or frothy or discolored water that shows that a color or detergent problem is present.

In industrial pump systems, the required driver power for the pump is related to head and to flow. The different types of drivers most commonly used include electric motors, internal combustion engines, steam and gas turbines, and hydraulic power recovery turbines.

Have you ever heard of the expression “the parish pump”? It was a term coined through parts of the British Isles because the water pump because the center of the community. People would talk about local issues as they were getting water.

Every pump system varies slightly to fit all of the different measurements and parameters depending on your well, the layout of all the components, and the nature of your ground water. A well expert takes all of this into account to give a well pump that perfectly fits your situation.

Check the energy output of your pump; if more than 25 percent of it is being used to overcome friction, you may want to consider increasing the size of the pipes to reduce friction.

If you notice a slight change in the water pressure or content, it may be a sign of a well water pump malfunction. Although well pumps are very durable, they sometimes experience symptoms of failure.

Bigger is better when it comes to the size of the tanks for water storage. The larger the tank, the better because the pump has a longer wait time between cycles. When the pump does run, it runs longer which in turn extends the life of the pump motor and reduces electricity usage.

Did you know that you should stay away from your well pump after a heavy rain or other incident involving water? In fact, your well pump when flooded, for any reason, should always be avoided to reduce the possibility of electric shock.

If your home is at the end of a water supply line, you may experience chronically weak water pressure. In this case, a booster pump can help even out the pressure to ensure proper operation of appliances and strong flow for showers.