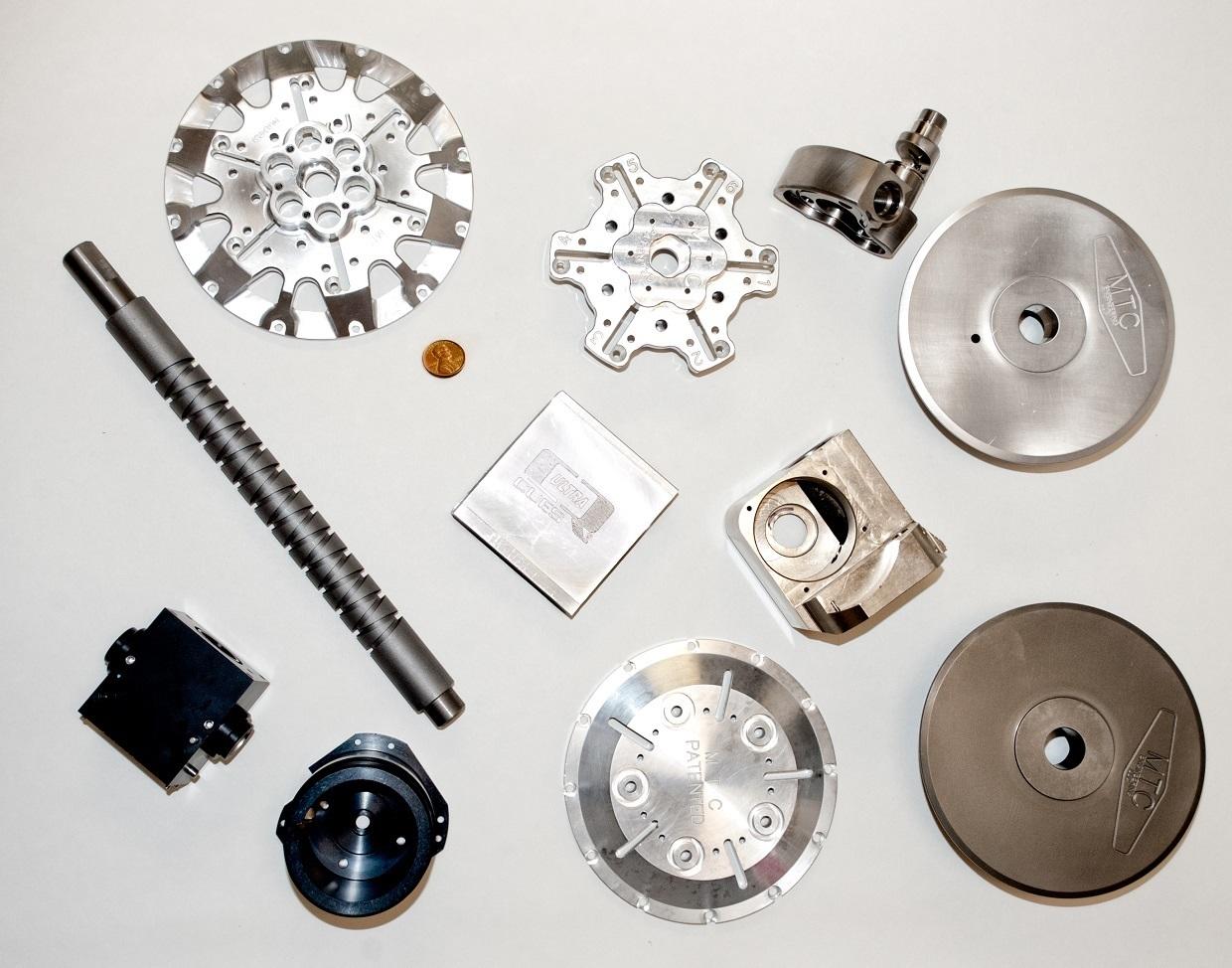

JW Machine has the clients, experience and awards, which is why we are Orlando’s premier contract manufacturing and small part machining facility. We are ready to serve any industry with proven performance, give us a call today! https://jwmachinecorp.com/featured-service-contract-manufacturing/

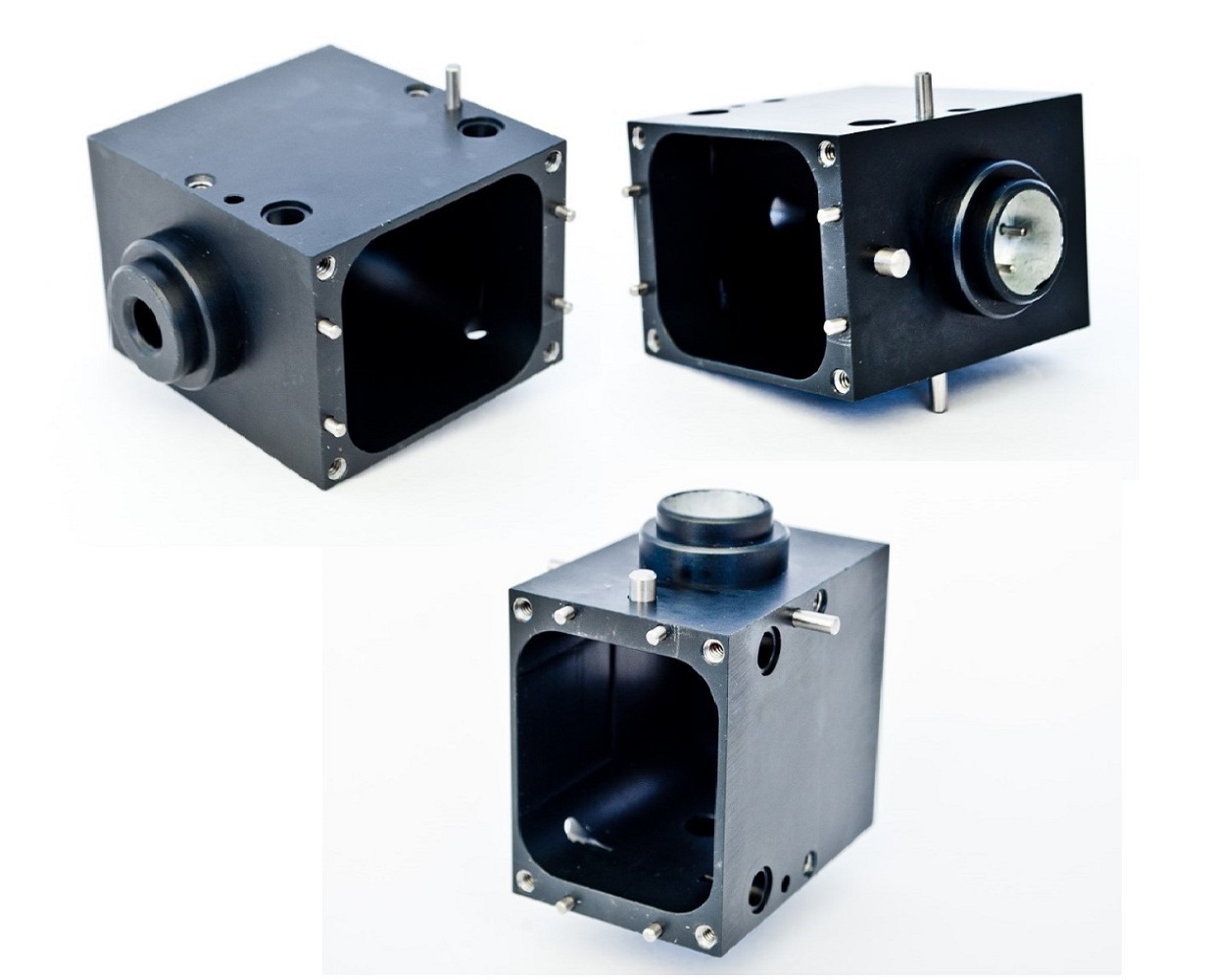

The CNC machinist plays an important role in any machine shop operation. This is especially true for precision CNC machining operations such as JW Machine. We are not only an AS 9100 certified machine shop, but we are also ISO 9001:2015 certified, JCP certified, SAM (CCR) registered, ITAR registered/compliant, MBE certified and MIL-SPEC Quality Compliance certified.

https://jwmachinecorp.com/the-cnc-machinist/

[AS 9100 D / ISO 9001:2015 Certified]

Visit our website: https://jwmachinecorp.com/

JWMACHINECORP.COM

The CNC Machinist : Part Two - JW Machine | Give us a call today!

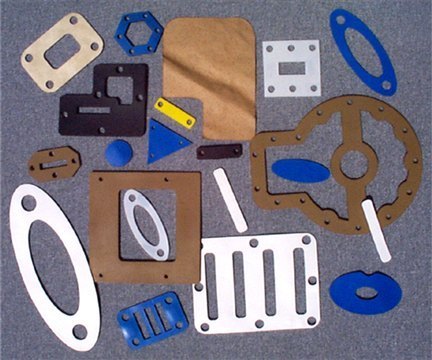

Whether its small part machining, milling turning, laser cutting, laser etching, laser engraving, or another precision CNC machining service, you want to make sure the machine shop you use is certified in quality assurance. https://jwmachinecorp.com/leader-in-small-part-machining/

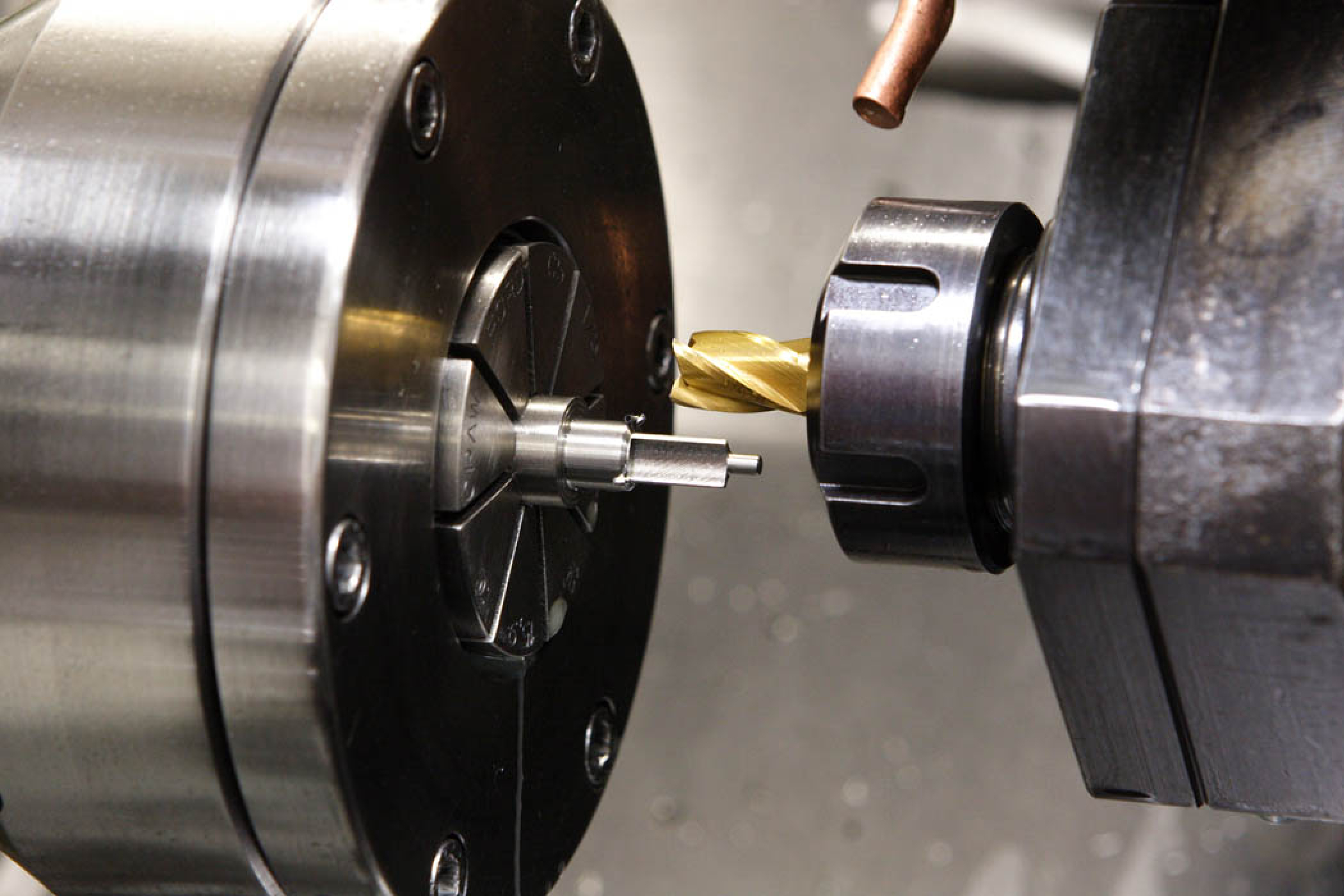

Small part machining to tolerances of one ten thousandth of an inch presents multiple challenges. All milling turning processes require some form of lubrication. https://jwmachinecorp.com/its-all-about-the-lubricant/

Although milling turning is a common term used in precision CNC machining, they are actually separate processes. Part one of our article will discuss milling turning and some of the differences between these two types of conventional machining operations. https://jwmachinecorp.com/milling-turning-the-differences/

During the Second Industrial Revolution, the blacksmith developed into what we now know today as the machine shop.

Learn more: https://jwmachinecorp.com/general-machine-shop-services/

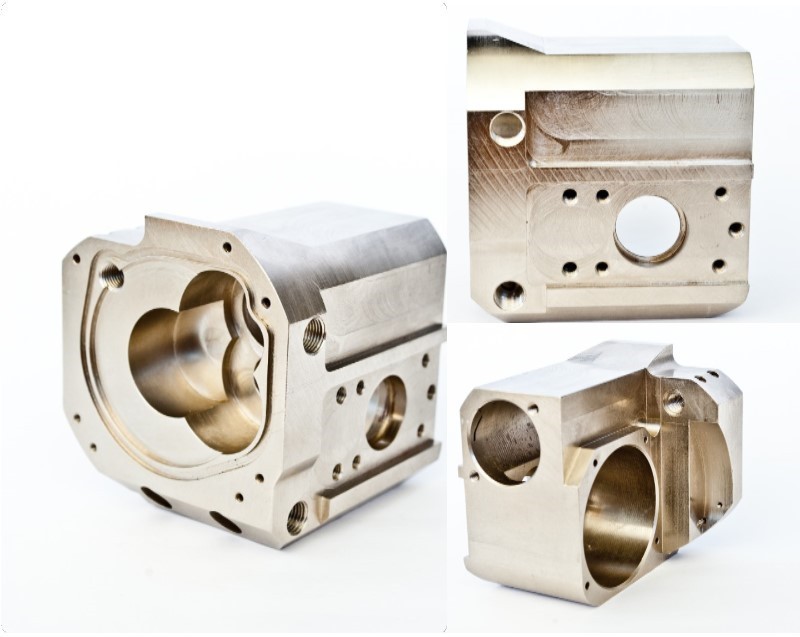

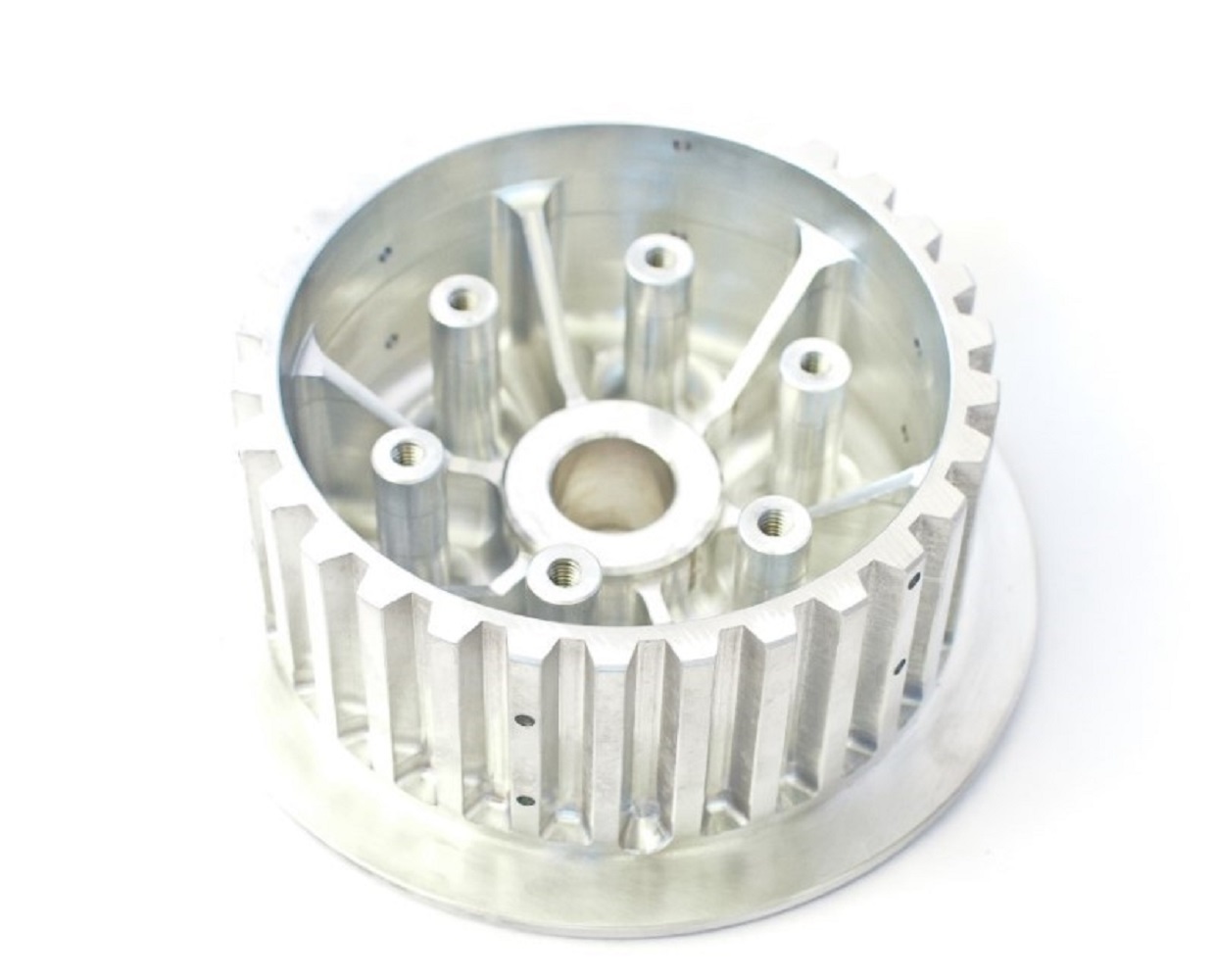

One of JW Machine’s many specialties is prototypes to production manufacturing. Our machine shop is proficient in small part machining, close tolerance machining, milling, turning, and machining center. https://jwmachinecorp.com/prototypes-to-production-manufacturing/

JW Machine is one of the premier machine shop services that supports industry. Whether it is small part machining, reproduction, or complete prototypes to production manufacturer services, we are ready to assist you in helping your business succeed. https://jwmachinecorp.com/general-machine-shop-services/

Laser engraving and laser cutting has risen to a whole new level as laser technology continues to evolve. JW Machine’s advanced laser engraving and laser cutting equipment, coupled with the knowledge and experience of our operators, allows us to meet your company’s laser engraving service needs. https://jwmachinecorp.com/laser-cutting-laser-engraving/

JW Machine is one of the premier machine shop services that supports industry. Whether it is small part machining, reproduction, or complete prototypes to production manufacturer services, we are ready to assist you in helping your business succeed. https://jwmachinecorp.com/general-machine-shop-services/

Laser engraving leaves a deep, clear and permanent impression on the surface of a part or component. Metals are the most common surfaces that utilize this process. However, laser engraving is perfect for a variety of surfaces.

https://jwmachinecorp.com/common-surfaces-utilize-laser-engraving/

Automated CNC milling turning centers are able to produce either one or 1000 of the same component. A CNC machining center can reproduce any number of components with little or no supervision and can rapidly change to a new product with minimal down time. https://jwmachinecorp.com/why-is-automation-critical/

When it comes to our laser etching and laser engraving service, just about anything is possible! Some popular laser etching and laser engraving applications include part numbers, logos, bar codes and serialization of parts. https://jwmachinecorp.com/laser-etching/

Aerospace manufacturing is a very specialized process that requires expert precision CNC machine shop capabilities. JW Machine is proud to work with several aerospace industry clients who appreciate our capabilities and value our certifications.

https://jwmachinecorp.com/cnc-machine-aerospace-manufacturing/

Our machine shop provides every level of service for your precision CNC machining project. JW Machine will be happy to quote you on any precision CNC machining need. Just give us a call! https://jwmachinecorp.com/cnc-machine-shop/

Laser cutting is very accurate even with small details. Plasma is used for just cutting metal, while laser cutting can be applied to all types of materials. https://jwmachinecorp.com/laser-cutting-vs-plasma-cutting/

Whether it’s small part machining, close tolerance machining, milling and turning, laser engraving, laser cutting or another CNC machining service, automation has changed the industry for the better. https://jwmachinecorp.com/automation-has-transformed-manufacturing

JW Machine partners with many clients in the aerospace industry, including some within the Department of Defense. https://jwmachinecorp.com/laser-engraving-and-aerospace-industry/

To all those who have served and are still serving, we thank you.

[AS 9100 D / ISO 9001:2015 Certified]

Visit our website: https://jwmachinecorp.com/

Not only does the laser etching need to be readable, but it must be accurate. A single mistake on the laser engraving of even the tiniest part can have significant consequences. Precision does matter! https://jwmachinecorp.com/precision-matters/

Plasma cutting was developed in the 1950s specifically for metals that could not be cut by a flame including copper, stainless steel and aluminum. Laser cutting uses a precision laser to penetrate materials including strong metals such as stainless steel. https://jwmachinecorp.com/laser-cutting-vs-plasma-cutting/

As the popularity of 3D printing is on the rise, we are often asked by customers to describe the differences between precision CNC machining and 3D printing.

[AS 9100 D / ISO 9001:2015 Certified]

Visit our website: https://jwmachinecorp.com/

JWMACHINECORP.COM

Precision CNC Machining vs. 3D Printing: A Closer Look

When it comes to precision CNC machining, JW Machine is your source for experienced, high quality services.

[AS 9100 D / ISO 9001:2015 Certified]

Visit our website: https://jwmachinecorp.com/

JWMACHINECORP.COM

A Closer Look at Precision CNC Machining vs. 3D Printing

Whether its small part machining, milling turning, laser cutting, laser etching, laser engraving, or another precision CNC machining service, you want to make sure the machine shop you use is certified in quality assurance. https://jwmachinecorp.com/leader-in-small-part-machining/

Steel can be used in milling turning, laser cutting, laser engraving, laser etching, small part machining, close tolerance machining and many other machine shop operations.

[AS 9100 D / ISO 9001:2015 Certified]

Visit our website: https://jwmachinecorp.com/

JWMACHINECORP.COM

Metals and Precision CNC Machining - Close Tolerance Machining

We are thankful for you! Happy Thanksgiving!

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

We thought it would be fun to lighten the mood and share some interesting tidbits about precision CNC machining.

[AS 9100 D / ISO 9001:2015 Certified]

Visit our website: https://jwmachinecorp.com/

JWMACHINECORP.COM

Fun Tidbits About Precision CNC Machining - JW Machine

When it comes to our laser etching and laser engraving service, just about anything is possible! Some popular laser etching and laser engraving applications include part numbers, logos, bar codes and serialization of parts. https://jwmachinecorp.com/laser-etching/

Laser engraving adapters are very expensive and require significant set-up time and testing. A machine shop laser engraving service will have the appropriate equipment and experts to perform the laser engraving right the first time. https://jwmachinecorp.com/why-not-diy/

[AS 9100 D / ISO 9001:2015 Certified]

Visit our website: https://jwmachinecorp.com/

JWMACHINECORP.COM

Metals Used in Precision CNC Machining - ISO 9100 / AS 9100 Certified

[AS 9100 D / ISO 9001:2015 Certified]

Visit our website: https://jwmachinecorp.com/

JWMACHINECORP.COM

Precision CNC Machining and Metals - ISO 9100 / AS 9100 Certified

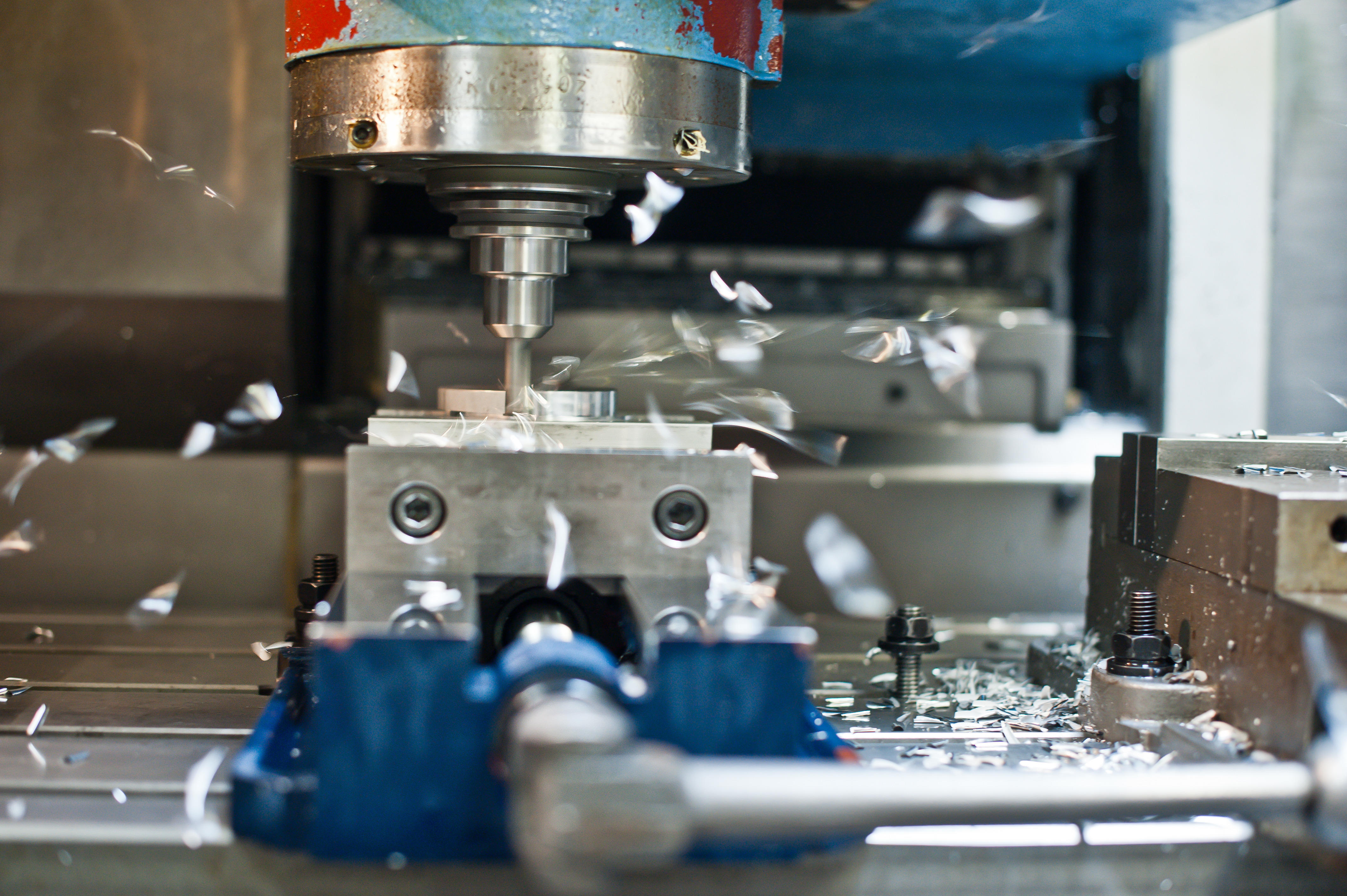

Our CNC milling centers are capable of high-speed small part machining with tolerances to one ten thousandth of an inch. Our milling centers are operated by experts that have only one mission in mind, your contract manufacturing project. https://jwmachinecorp.com/featured-service-milling-turning/

[AS 9100 D / ISO 9001:2015 Certified]

Visit our website: https://jwmachinecorp.com/

JWMACHINECORP.COM

The Role of the CNC Machinist - JW Machine | Call us today!

[AS 9100 D / ISO 9001:2015 Certified]

Visit our website: https://jwmachinecorp.com/

JWMACHINECORP.COM

The CNC Machinist : Part Two - JW Machine | Give us a call today!

Our ninety-five years of combined contract manufacturing and precision CNC machining experience means your contract manufacturing or small part machining project will exceed your expectations. https://jwmachinecorp.com/jw-machine-who-are-we/

[AS 9100 D / ISO 9001:2015 Certified]

Visit our website: https://jwmachinecorp.com/

JWMACHINECORP.COM

Qualities to Consider When Selecting a Precision CNC Machining Facility

[AS 9100 D / ISO 9001:2015 Certified]

Visit our website: https://jwmachinecorp.com/

JWMACHINECORP.COM

Qualities to Consider When Selecting a Precision CNC Machine Shop

During the Second Industrial Revolution, the blacksmith developed into what we now know today as the machine shop.

Learn more: https://jwmachinecorp.com/general-machine-shop-services/

Milling turning is not a single process, but two separate subtractive manufacturing operations. A quality CNC machine shop will be able to explain milling turning differences and similarities and discuss why one may be preferred for your particular job. https://jwmachinecorp.com/milling-turning-similar-but-different/

Costs Associated with Precision CNC Machining

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

JWMACHINECORP.COM

Costs Associated with Precision CNC Machining - Contract Manufacturing

Small part machining to tolerances of one ten thousandth of an inch presents multiple challenges. All milling turning processes require some form of lubrication. https://jwmachinecorp.com/its-all-about-the-lubricant/

Although milling turning is a common term used in precision CNC machining, they are actually separate processes. Part one of our article will discuss milling turning and some of the differences between these two types of conventional machining operations. https://jwmachinecorp.com/milling-turning-the-differences/

JW Machine has the clients, experience and awards, which is why we are Orlando’s premier contract manufacturing and small part machining facility. We are ready to serve any industry with proven performance, give us a call today! https://jwmachinecorp.com/featured-service-contract-manufacturing/

Whether its small part machining, milling turning, laser cutting, laser etching, laser engraving, or another precision CNC machining service, you want to make sure the machine shop you use is certified in quality assurance. https://jwmachinecorp.com/leader-in-small-part-machining/

Precision CNC Machining vs. Standard Machining

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

JWMACHINECORP.COM

Precision CNC Machining vs. Standard Machining

The holiday season is a time of giving, and we’d like to give you a huge thanks for being our cherished customer. Have a joyous holiday season and a very happy New Year.

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

Laser engraving and laser cutting has risen to a whole new level as laser technology continues to evolve. JW Machine’s advanced laser engraving and laser cutting equipment, coupled with the knowledge and experience of our operators, allows us to meet your company’s laser engraving service needs. https://jwmachinecorp.com/laser-cutting-laser-engraving/

We wish you all the best in 2021! Happy New Year!

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

The CNC machinist plays an important role in any machine shop operation. This is especially true for precision CNC machining operations such as JW Machine. We are not only an AS 9100 certified machine shop, but we are also ISO 9001:2015 certified, JCP certified, SAM (CCR) registered, ITAR registered/compliant, MBE certified and MIL-SPEC Quality Compliance certified.

https://jwmachinecorp.com/the-cnc-machinist/

[AS 9100 D / ISO 9001:2015 Certified]

Visit our website: https://jwmachinecorp.com/

JWMACHINECORP.COM

The CNC Machinist : Part Two - JW Machine | Give us a call today!

Precision CNC Machining: What Affects the Cost?

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

JWMACHINECORP.COM

Precision CNC Machining: What Can Affect the Cost?

One of JW Machine’s many specialties is prototypes to production manufacturing. Our machine shop is proficient in small part machining, close tolerance machining, milling, turning, and machining center. https://jwmachinecorp.com/prototypes-to-production-manufacturing/

JW Machine is one of the premier machine shop services that supports industry. Whether it is small part machining, reproduction, or complete prototypes to production manufacturer services, we are ready to assist you in helping your business succeed. https://jwmachinecorp.com/general-machine-shop-services/

JW Machine is one of the premier machine shop services that supports industry. Whether it is small part machining, reproduction, or complete prototypes to production manufacturer services, we are ready to assist you in helping your business succeed. https://jwmachinecorp.com/general-machine-shop-services/

One of JW Machine’s many specialties is prototypes to production manufacturing. Our machine shop is proficient in small part machining, close tolerance machining, milling, turning, and machining center. https://jwmachinecorp.com/prototypes-to-production-manufacturing/

JW Machine is one of the premier machine shop services that supports industry. Whether it is small part machining, reproduction, or complete prototypes to production manufacturer services, we are ready to assist you in helping your business succeed. https://jwmachinecorp.com/general-machine-shop-services/

Laser engraving leaves a deep, clear and permanent impression on the surface of a part or component. Metals are the most common surfaces that utilize this process. However, laser engraving is perfect for a variety of surfaces.

https://jwmachinecorp.com/common-surfaces-utilize-laser-engraving/

Automated CNC milling turning centers are able to produce either one or 1000 of the same component. A CNC machining center can reproduce any number of components with little or no supervision and can rapidly change to a new product with minimal down time. https://jwmachinecorp.com/why-is-automation-critical/

JW Machine is one of the premier machine shop services that supports industry. Whether it is small part machining, reproduction, or complete prototypes to production manufacturer services, we are ready to assist you in helping your business succeed. https://jwmachinecorp.com/general-machine-shop-services/

One of JW Machine’s many specialties is prototypes to production manufacturing. Our machine shop is proficient in small part machining, close tolerance machining, milling, turning, and machining center. https://jwmachinecorp.com/prototypes-to-production-manufacturing/

JW Machine is one of the premier machine shop services that supports industry. Whether it is small part machining, reproduction, or complete prototypes to production manufacturer services, we are ready to assist you in helping your business succeed. https://jwmachinecorp.com/general-machine-shop-services/

When it comes to our laser etching and laser engraving service, just about anything is possible! Some popular laser etching and laser engraving applications include part numbers, logos, bar codes and serialization of parts. https://jwmachinecorp.com/laser-etching/

Aerospace manufacturing is a very specialized process that requires expert precision CNC machine shop capabilities. JW Machine is proud to work with several aerospace industry clients who appreciate our capabilities and value our certifications.

https://jwmachinecorp.com/cnc-machine-aerospace-manufacturing/

Laser engraving leaves a deep, clear and permanent impression on the surface of a part or component. Metals are the most common surfaces that utilize this process. However, laser engraving is perfect for a variety of surfaces.

https://jwmachinecorp.com/common-surfaces-utilize-laser-engraving/

Automated CNC milling turning centers are able to produce either one or 1000 of the same component. A CNC machining center can reproduce any number of components with little or no supervision and can rapidly change to a new product with minimal down time. https://jwmachinecorp.com/why-is-automation-critical/

JW Machine is one of the premier machine shop services that supports industry. Whether it is small part machining, reproduction, or complete prototypes to production manufacturer services, we are ready to assist you in helping your business succeed. https://jwmachinecorp.com/general-machine-shop-services/

One of JW Machine’s many specialties is prototypes to production manufacturing. Our machine shop is proficient in small part machining, close tolerance machining, milling, turning, and machining center. https://jwmachinecorp.com/prototypes-to-production-manufacturing/

Our machine shop provides every level of service for your precision CNC machining project. JW Machine will be happy to quote you on any precision CNC machining need. Just give us a call! https://jwmachinecorp.com/cnc-machine-shop/

Laser cutting is very accurate even with small details. Plasma is used for just cutting metal, while laser cutting can be applied to all types of materials. https://jwmachinecorp.com/laser-cutting-vs-plasma-cutting/

When it comes to our laser etching and laser engraving service, just about anything is possible! Some popular laser etching and laser engraving applications include part numbers, logos, bar codes and serialization of parts. https://jwmachinecorp.com/laser-etching/

Aerospace manufacturing is a very specialized process that requires expert precision CNC machine shop capabilities. JW Machine is proud to work with several aerospace industry clients who appreciate our capabilities and value our certifications.

https://jwmachinecorp.com/cnc-machine-aerospace-manufacturing/

Laser engraving leaves a deep, clear and permanent impression on the surface of a part or component. Metals are the most common surfaces that utilize this process. However, laser engraving is perfect for a variety of surfaces.

https://jwmachinecorp.com/common-surfaces-utilize-laser-engraving/

Automated CNC milling turning centers are able to produce either one or 1000 of the same component. A CNC machining center can reproduce any number of components with little or no supervision and can rapidly change to a new product with minimal down time. https://jwmachinecorp.com/why-is-automation-critical/

Not only does the laser etching need to be readable, but it must be accurate. A single mistake on the laser engraving of even the tiniest part can have significant consequences. Precision does matter! https://jwmachinecorp.com/precision-matters/

Part Two We are continuing our series on preparing for the prototypes to production manufacturing process. Our previous article discussed developing a concept and planning a budget. Today, we will examine two more areas that play a crucial role in ensuring your project is delivered on-time and within budget. Let’s take a look: Material Selection Material selection is an important ... The post Prototypes to Production Manufacturing: The Process appeared first on JW Machine.

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

JWMACHINECORP.COM

Prototypes to Production Manufacturing: The Process

Part One We believe pre-planning is imperative to ensuring each job is delivered on-time and within budget. There are many considerations when it comes to any precision CNC machining project. We are beginning a new series on steps to take when preparing for the prototypes to production manufacturing process. Concept The prototypes to production manufacturing process begins with a concept. ... The post Preparing for the Prototypes to Production Manufacturing Process appeared first on JW Machine.

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

JWMACHINECORP.COM

Preparing for the Prototypes to Production Manufacturing Process

Our machine shop provides every level of service for your precision CNC machining project. JW Machine will be happy to quote you on any precision CNC machining need. Just give us a call! https://jwmachinecorp.com/cnc-machine-shop/

Laser cutting is very accurate even with small details. Plasma is used for just cutting metal, while laser cutting can be applied to all types of materials. https://jwmachinecorp.com/laser-cutting-vs-plasma-cutting/

When it comes to our laser etching and laser engraving service, just about anything is possible! Some popular laser etching and laser engraving applications include part numbers, logos, bar codes and serialization of parts. https://jwmachinecorp.com/laser-etching/

Whether it’s small part machining, close tolerance machining, milling and turning, laser engraving, laser cutting or another CNC machining service, automation has changed the industry for the better. https://jwmachinecorp.com/automation-has-transformed-manufacturing

Part Two We are continuing our series on machine shop qualities that are important when working with the defense and military industries. Our previous article discussed the level of experience of the precision CNC machining professionals, machine shop certifications, and the importance of maintaining confidentiality. Today, we will take a closer look at three more important qualities to consider. Technology ... The post Defense and Military Industries appeared first on JW Machine.

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

JWMACHINECORP.COM

Defense and Military Industries - Precision CNC Machining

Part One We are beginning a new series of articles on working with defense and military clients. These sensitive industries have unique needs and considerations, which is why it is important for the machine shop handling your military and defense projects to be a good match. Let’s take a closer look. Experience Experience matters when it comes to precision CNC ... The post What Matters Most When Working with Defense and Military Industries appeared first on JW Machine.

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

JWMACHINECORP.COM

What Matters Most When Working with Defense and Military Industries

JW Machine partners with many clients in the aerospace industry, including some within the Department of Defense. https://jwmachinecorp.com/laser-engraving-and-aerospace-industry/

Not only does the laser etching need to be readable, but it must be accurate. A single mistake on the laser engraving of even the tiniest part can have significant consequences. Precision does matter! https://jwmachinecorp.com/precision-matters/

Part Two We are continuing our series on preparing for the prototypes to production manufacturing process. Our previous article discussed developing a concept and planning a budget. Today, we will examine two more areas that play a crucial role in ensuring your project is delivered on-time and within budget. Let’s take a look: Material Selection Material selection is an important ... The post Prototypes to Production Manufacturing: The Process appeared first on JW Machine.

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

JWMACHINECORP.COM

Prototypes to Production Manufacturing: The Process

When it comes to our laser etching and laser engraving service, just about anything is possible! Some popular laser etching and laser engraving applications include part numbers, logos, bar codes and serialization of parts. https://jwmachinecorp.com/laser-etching/

Most precision CNC machining facilities state that they work with stainless steel. However, doing it well requires special skills, craftsmanship and experience. Today’s article will take an in-depth look at stainless steel, common applications, and what it takes to properly machine this very versatile alloy. Families of Stainless Steel There are more than 150 families of stainless steel, each with ... The post The Art of Machining Stainless Steel appeared first on JW Machine.

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

JWMACHINECORP.COM

The Art of Machining Stainless Steel - Precision CNC Machining

Plasma cutting was developed in the 1950s specifically for metals that could not be cut by a flame including copper, stainless steel and aluminum. Laser cutting uses a precision laser to penetrate materials including strong metals such as stainless steel. https://jwmachinecorp.com/laser-cutting-vs-plasma-cutting/

Whether it’s small part machining, close tolerance machining, milling and turning, laser engraving, laser cutting or another CNC machining service, automation has changed the industry for the better. https://jwmachinecorp.com/automation-has-transformed-manufacturing

Part Two We are continuing our series on machine shop qualities that are important when working with the defense and military industries. Our previous article discussed the level of experience of the precision CNC machining professionals, machine shop certifications, and the importance of maintaining confidentiality. Today, we will take a closer look at three more important qualities to consider. Technology ... The post Defense and Military Industries appeared first on JW Machine.

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

JWMACHINECORP.COM

Defense and Military Industries - Precision CNC Machining

Part One We are beginning a new series of articles on working with defense and military clients. These sensitive industries have unique needs and considerations, which is why it is important for the machine shop handling your military and defense projects to be a good match. Let’s take a closer look. Experience Experience matters when it comes to precision CNC ... The post What Matters Most When Working with Defense and Military Industries appeared first on JW Machine.

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

JWMACHINECORP.COM

What Matters Most When Working with Defense and Military Industries

Whether its small part machining, milling turning, laser cutting, laser etching, laser engraving, or another precision CNC machining service, you want to make sure the machine shop you use is certified in quality assurance. https://jwmachinecorp.com/leader-in-small-part-machining/

When it comes to our laser etching and laser engraving service, just about anything is possible! Some popular laser etching and laser engraving applications include part numbers, logos, bar codes and serialization of parts. https://jwmachinecorp.com/laser-etching/

Most precision CNC machining facilities state that they work with stainless steel. However, doing it well requires special skills, craftsmanship and experience. Today’s article will take an in-depth look at stainless steel, common applications, and what it takes to properly machine this very versatile alloy. Families of Stainless Steel There are more than 150 families of stainless steel, each with ... The post The Art of Machining Stainless Steel appeared first on JW Machine.

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

JWMACHINECORP.COM

The Art of Machining Stainless Steel - Precision CNC Machining

Plasma cutting was developed in the 1950s specifically for metals that could not be cut by a flame including copper, stainless steel and aluminum. Laser cutting uses a precision laser to penetrate materials including strong metals such as stainless steel. https://jwmachinecorp.com/laser-cutting-vs-plasma-cutting/

Whether it’s small part machining, close tolerance machining, milling and turning, laser engraving, laser cutting or another CNC machining service, automation has changed the industry for the better. https://jwmachinecorp.com/automation-has-transformed-manufacturing

Part Two We are continuing our series on machine shop qualities that are important when working with the defense and military industries. Our previous article discussed the level of experience of the precision CNC machining professionals, machine shop certifications, and the importance of maintaining confidentiality. Today, we will take a closer look at three more important qualities to consider. Technology ... The post Defense and Military Industries appeared first on JW Machine.

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

JWMACHINECORP.COM

Defense and Military Industries - Precision CNC Machining

Laser engraving adapters are very expensive and require significant set-up time and testing. A machine shop laser engraving service will have the appropriate equipment and experts to perform the laser engraving right the first time. https://jwmachinecorp.com/why-not-diy/

Our CNC milling centers are capable of high-speed small part machining with tolerances to one ten thousandth of an inch. Our milling centers are operated by experts that have only one mission in mind, your contract manufacturing project. https://jwmachinecorp.com/featured-service-milling-turning/

Whether its small part machining, milling turning, laser cutting, laser etching, laser engraving, or another precision CNC machining service, you want to make sure the machine shop you use is certified in quality assurance. https://jwmachinecorp.com/leader-in-small-part-machining/

When it comes to our laser etching and laser engraving service, just about anything is possible! Some popular laser etching and laser engraving applications include part numbers, logos, bar codes and serialization of parts. https://jwmachinecorp.com/laser-etching/

Most precision CNC machining facilities state that they work with stainless steel. However, doing it well requires special skills, craftsmanship and experience. Today’s article will take an in-depth look at stainless steel, common applications, and what it takes to properly machine this very versatile alloy. Families of Stainless Steel There are more than 150 families of stainless steel, each with ... The post The Art of Machining Stainless Steel appeared first on JW Machine.

.....

(407) 298-9171

https://jwmachinecorp.com

AS 9100 D / ISO 9001:2015 Certified

JWMACHINECORP.COM

The Art of Machining Stainless Steel - Precision CNC Machining

Plasma cutting was developed in the 1950s specifically for metals that could not be cut by a flame including copper, stainless steel and aluminum. Laser cutting uses a precision laser to penetrate materials including strong metals such as stainless steel. https://jwmachinecorp.com/laser-cutting-vs-plasma-cutting/

Milling turning is not a single process, but two separate subtractive manufacturing operations. A quality CNC machine shop will be able to explain milling turning differences and similarities and discuss why one may be preferred for your particular job. https://jwmachinecorp.com/milling-turning-similar-but-different/

Our ninety-five years of combined contract manufacturing and precision CNC machining experience means your contract manufacturing or small part machining project will exceed your expectations. https://jwmachinecorp.com/jw-machine-who-are-we/

Laser engraving adapters are very expensive and require significant set-up time and testing. A machine shop laser engraving service will have the appropriate equipment and experts to perform the laser engraving right the first time. https://jwmachinecorp.com/why-not-diy/

Our CNC milling centers are capable of high-speed small part machining with tolerances to one ten thousandth of an inch. Our milling centers are operated by experts that have only one mission in mind, your contract manufacturing project. https://jwmachinecorp.com/featured-service-milling-turning/

Whether its small part machining, milling turning, laser cutting, laser etching, laser engraving, or another precision CNC machining service, you want to make sure the machine shop you use is certified in quality assurance. https://jwmachinecorp.com/leader-in-small-part-machining/

When it comes to our laser etching and laser engraving service, just about anything is possible! Some popular laser etching and laser engraving applications include part numbers, logos, bar codes and serialization of parts. https://jwmachinecorp.com/laser-etching/

During the Second Industrial Revolution, the blacksmith developed into what we now know today as the machine shop.

Learn more: https://jwmachinecorp.com/general-machine-shop-services/

Milling turning is not a single process, but two separate subtractive manufacturing operations. A quality CNC machine shop will be able to explain milling turning differences and similarities and discuss why one may be preferred for your particular job. https://jwmachinecorp.com/milling-turning-similar-but-different/

Our ninety-five years of combined contract manufacturing and precision CNC machining experience means your contract manufacturing or small part machining project will exceed your expectations. https://jwmachinecorp.com/jw-machine-who-are-we/

Laser engraving adapters are very expensive and require significant set-up time and testing. A machine shop laser engraving service will have the appropriate equipment and experts to perform the laser engraving right the first time. https://jwmachinecorp.com/why-not-diy/

Our CNC milling centers are capable of high-speed small part machining with tolerances to one ten thousandth of an inch. Our milling centers are operated by experts that have only one mission in mind, your contract manufacturing project. https://jwmachinecorp.com/featured-service-milling-turning/

Whether its small part machining, milling turning, laser cutting, laser etching, laser engraving, or another precision CNC machining service, you want to make sure the machine shop you use is certified in quality assurance. https://jwmachinecorp.com/leader-in-small-part-machining/

Small part machining to tolerances of one ten thousandth of an inch presents multiple challenges. All milling turning processes require some form of lubrication. https://jwmachinecorp.com/its-all-about-the-lubricant/

Although milling turning is a common term used in precision CNC machining, they are actually separate processes. Part one of our article will discuss milling turning and some of the differences between these two types of conventional machining operations. https://jwmachinecorp.com/milling-turning-the-differences/

During the Second Industrial Revolution, the blacksmith developed into what we now know today as the machine shop.

Learn more: https://jwmachinecorp.com/general-machine-shop-services/

Milling turning is not a single process, but two separate subtractive manufacturing operations. A quality CNC machine shop will be able to explain milling turning differences and similarities and discuss why one may be preferred for your particular job. https://jwmachinecorp.com/milling-turning-similar-but-different/

Our ninety-five years of combined contract manufacturing and precision CNC machining experience means your contract manufacturing or small part machining project will exceed your expectations. https://jwmachinecorp.com/jw-machine-who-are-we/

Laser engraving adapters are very expensive and require significant set-up time and testing. A machine shop laser engraving service will have the appropriate equipment and experts to perform the laser engraving right the first time. https://jwmachinecorp.com/why-not-diy/

Whether its small part machining, milling turning, laser cutting, laser etching, laser engraving, or another precision CNC machining service, you want to make sure the machine shop you use is certified in quality assurance. https://jwmachinecorp.com/leader-in-small-part-machining/

Small part machining to tolerances of one ten thousandth of an inch presents multiple challenges. All milling turning processes require some form of lubrication. https://jwmachinecorp.com/its-all-about-the-lubricant/

Although milling turning is a common term used in precision CNC machining, they are actually separate processes. Part one of our article will discuss milling turning and some of the differences between these two types of conventional machining operations. https://jwmachinecorp.com/milling-turning-the-differences/

During the Second Industrial Revolution, the blacksmith developed into what we now know today as the machine shop.

Learn more: https://jwmachinecorp.com/general-machine-shop-services/

Milling turning is not a single process, but two separate subtractive manufacturing operations. A quality CNC machine shop will be able to explain milling turning differences and similarities and discuss why one may be preferred for your particular job. https://jwmachinecorp.com/milling-turning-similar-but-different/

Our ninety-five years of combined contract manufacturing and precision CNC machining experience means your contract manufacturing or small part machining project will exceed your expectations. https://jwmachinecorp.com/jw-machine-who-are-we/