Why is screen printing more commonly known as silk screen printing? Because the screen mesh that is used during the printing process was once made of fine silk threads. Today, these threads are more commonly made of metal, nylon or polyester.

How does apparel screen printing compare to digital printing? Screen printing apparel services are usually much more affordable than digital printing services – especially for larger orders, and screen printing offers more variety in terms of color and designs.

The design on screen printed shirts typically stays in good shape for a long time. Therefore it makes sense to have your brand printed using this method as more people will be able to help you advertise your business.

Are you looking for the most cost-effective way to produce a large quantity of shirts or textile items? Screen printing is not only an inexpensive option, but also produces a durable finished product.

There are many advantages to the UV curable ink that is now widely used in the world of screen printing. It has excellent color value, it does not dry on the screen and so will not clog up a mesh, and it has a rapid cure time.

Did you know that despite being one of the softest fabrics used for screen printing, cotton is also one of the most durable? Cotton fabrics can endure tumble drying and even baking under low heat.

Why choose screen printing? Our custom screen printed products are produced by hand. We’re able to apply brilliantly colorful designs to materials like paper, fabric, glass and ceramic. And we can print items with curved or uneven surfaces like water bottles, mugs and drink cozies.

While the color of the fabric forms the backdrop, the type of ink used can create marvelous effects. Vary the ink to create raised surfaces, reflective designs - even have them shimmer through the addition of glitter. The choice is yours.

Are you interested in starting a t-shirt business? We can help through affordable screen printing services which can produce customized small to large t-shirts in no time. Plus, with today’s printing techniques we can perform lasting quality prints with a variety of colors and designs.

Fast Screen Printing Facts: The ancient Egyptians and Greeks used stenciling techniques as early as 2500 BC. The first patent for silk screen printing was awarded to Samuel Simon in 1907. John Pilsworth and his brothers began to use screen printing for posters in 1914.

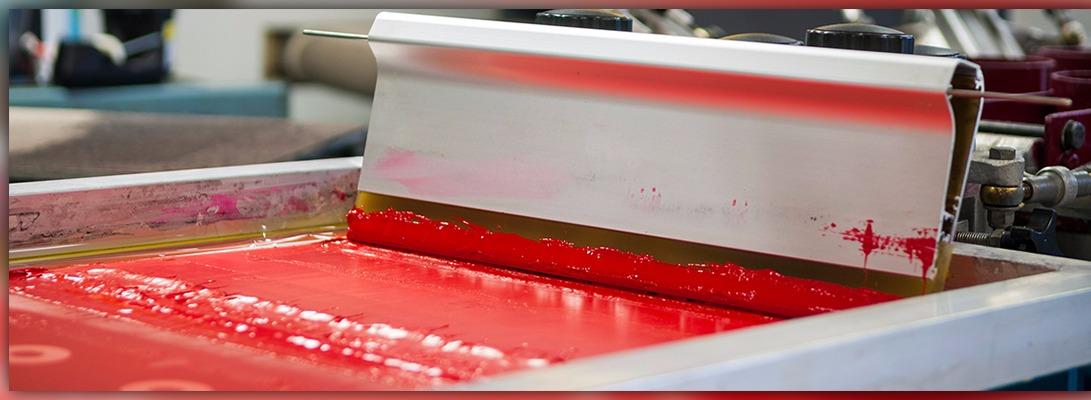

Ever wonder how screen printing is done? This process, also known as serigraphy, starts with an image that's transferred onto a screen with areas blocked off by stencil. Ink is then squeezed through the screen which then transfers the image onto the substrate.

Screen printing is often the best choice for promotional materials, whether that means stickers, signs, or t-shirts. The thick layer of ink possible with this printing method means logo colors will stay vivid, and the process also allows for flexibility in size and shape of the materials being printed.

Did you know that custom screen printing is a cost-effective and highly successful form of advertising? We offer a variety of screen printing services to meet all your marketing and promotional needs.

Have you printed shirts in the past that completely underwhelmed you with their lack of quality and clarity? We always strive to produce the highest quality results we can for the best price.

For businesses on a tight budget, customized screen printed t-shirts can provide an affordable alternative to uniforms. We can also work with your business to design a unique logo, and we can handle small to large orders.

One popular and fun idea is to create custom-printed mementos for those who attend special events like anniversary celebrations, birthday parties, bachelor and bachelorette parties, family reunions, charity events, weddings and more.

While the basic screen printing technique has not changed, the quality of the inks being used has greatly improved. This means that the prints are more durable and when used on clothes, will actually be able to move with the garment without cracking.

One major development in the modern screen printing process came in the 1910s, when printers Roy Beck, Charles Peter, and Edward Owens introduced the use of photoreactive chemicals to the process, thereby cutting down production times and increasing the level of detail that could be captured.

You can mix garments of different size, color, and style during your screen run as long as the design and the colors used remain the same throughout. If you are not sure, check with us beforehand to avoid problems.

Although the traditional material used for screen printing was silk (hence the alternate name "silk screening" for the procedure), today there are many different materials available. The most common mesh today is made of polyester, but other materials like nylon and stainless steel can be used for special purposes.

When you need an elaborate design and color combination, we use a four-color process. Black, Magenta, Yellow, and Cyan are the four colors used, and from these we are able to create tonal values to create the look you are after.

When it comes to our custom screen printing, we can create any look you have in mind. You can choose any layout, color, and design you desire, and we can even add photos if you choose.

Did you know? Screen printing is so popular because it is affordable and readily available. Many groups and organizations use it for movie posters, flyers, and more.

One of the most important things to get right would be your company's corporate identity. Therefore, employees participating in trade shows or events should always wear high-quality screen printed apparel that makes them readily identifiable.